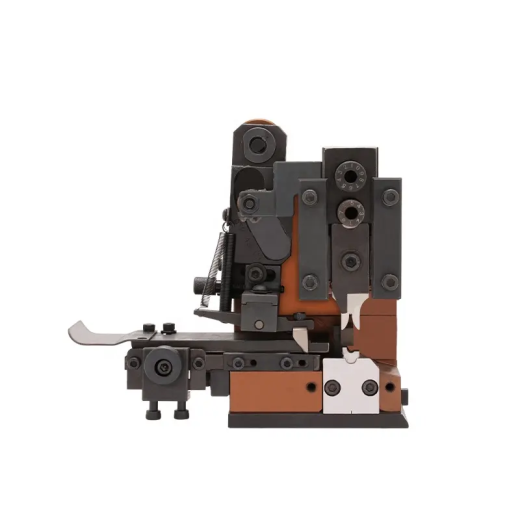

Customizable terminal blades - blades for different terminal crimping tools

Customizable terminal blades - blades for different terminal crimping tools

High-precision customization, OTP horizontal tools, horizontal and vertical molds, terminal molds, mold bases

High-precision customization, OTP horizontal tools, horizontal and vertical molds, terminal molds, mold bases

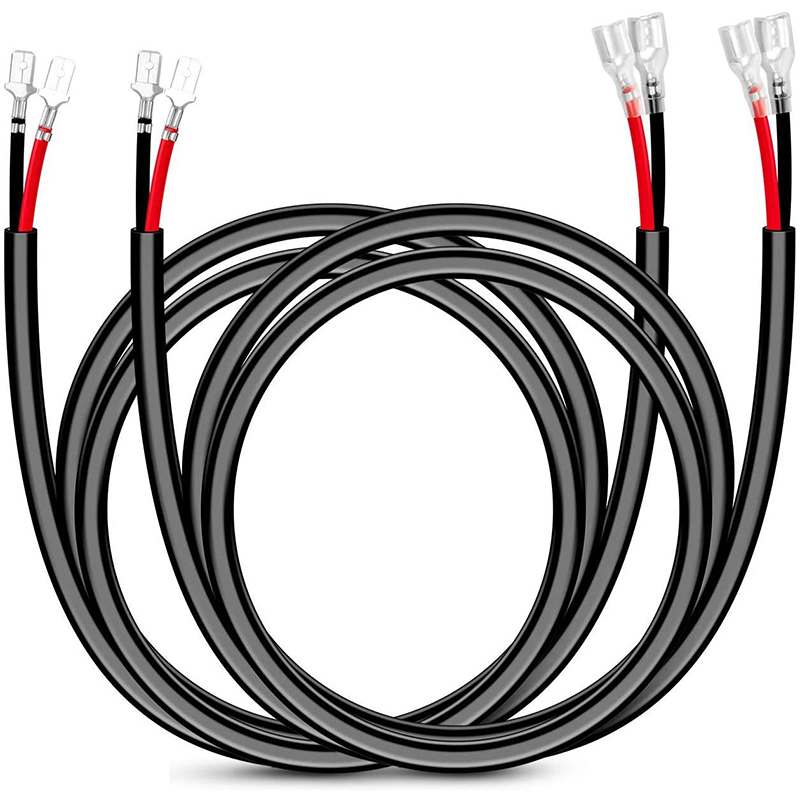

Cutting and Stripping Machine Rubber Wheel/Iron Wheel Wire Press

Cutting and Stripping Machine Rubber Wheel/Iron Wheel Wire Press

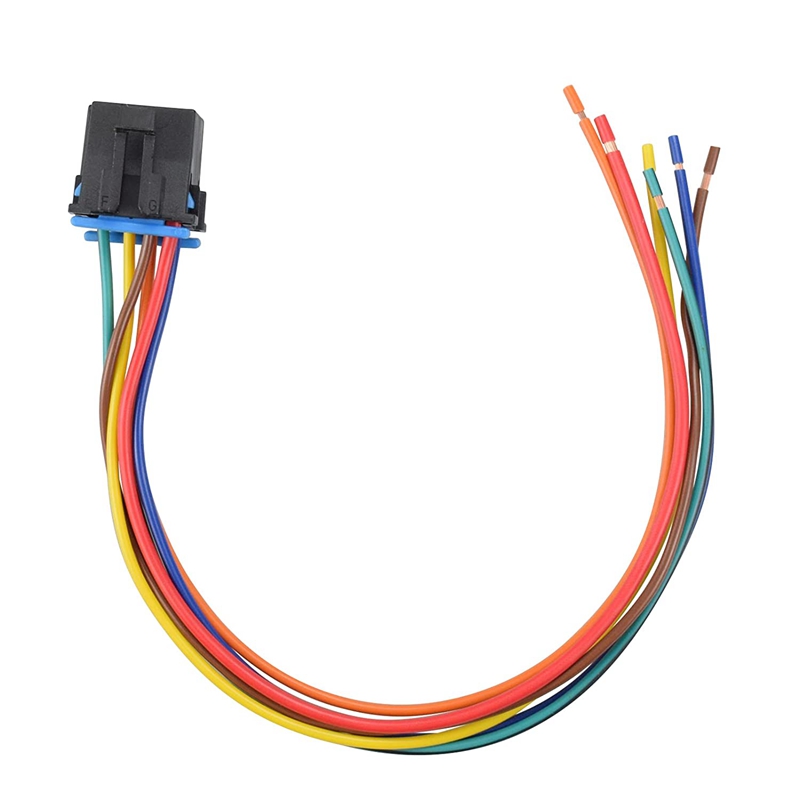

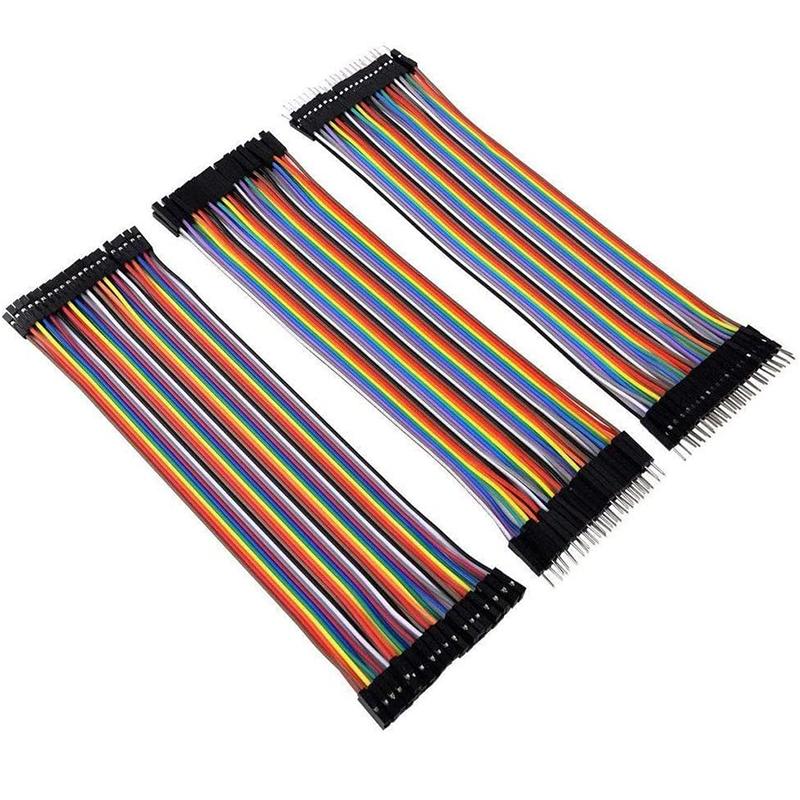

Automatic wire feeder, terminal machine supporting payoff tray

Automatic wire feeder, terminal machine supporting payoff tray