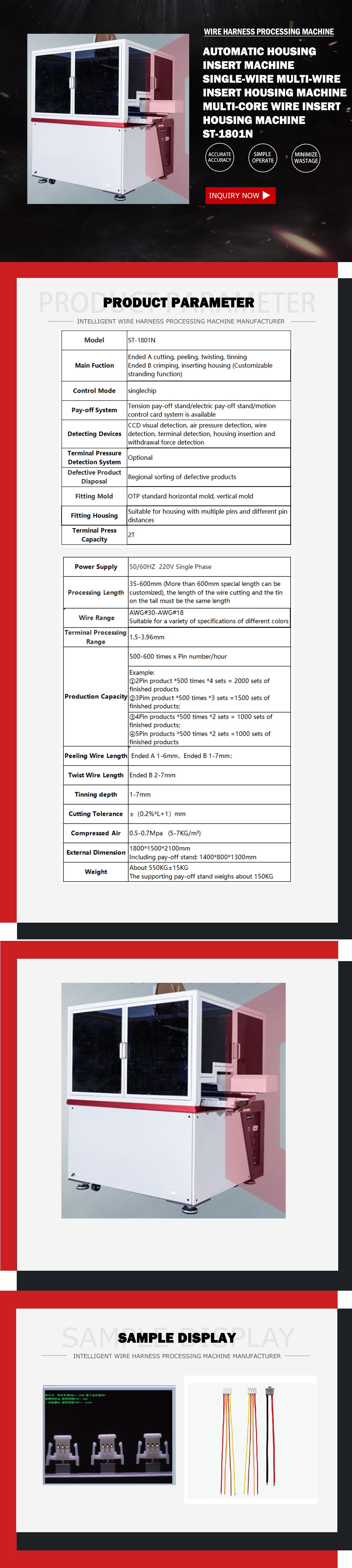

| ST-1801N fully automatic single-head end-piercing rubber shell machine configuration and product specifications | |

| 1. Equipment functions: | |

| Device name model | ST-1801N fully automatic single-end punching and end-piercing rubber shell machine |

| The main function | End A is cut, stripped, twisted and dipped in tin, end B is punched and put through a plastic shell (twisting function can be customized) |

| control method | Microcontroller |

| Pay-off system | Tension pay-off stand/electric pay-off stand/motion control card system optional |

| Detection device | CCD visual inspection, air pressure detection, wire presence detection, terminal presence detection, rubber shell insertion and extraction force detection |

| Terminal pressure detection system | Can be optionally installed (applicable to both domestic and imported systems) |

| Disposal of defective products | Defective product area sorting |

| Adapting mold | OTP standard transverse mold |

| Applicable plastic shell | Suitable for plastic shells with multiple pins and different pin spacings |

| Terminal crimping ability | 2T ultra-quiet servo terminal machine |

| 2. Technical parameters | |

| Power supply | 50/60HZ 220V single phase |

| Processing length | 30-600mm (special order is required for sizes larger than 600mm), the length of the cutting wire and the tinned tail must be the same length |

| Wire processing wire range | AWG#30-AWG#18, suitable for wires of various specifications and colors |

| Processable terminal spacing | 1.5-3.96mm |

| Capacity | 500-600 Times _ _ Finished products; ④5P products*500 times*2 sets, 1000 sets of finished products |

| Peeling length | A-side 1-6mm, B-side 1-7mm; |

| Twisted wire length | B end 2-7mm |

| tin dipping depth | 1-7mm |

| Cutting accuracy | ±(0.2%*L+1)mm |

| air pressure | 0.5-0.7Mpa (5-7KG/m3) |

| Dimensions | 1800*1500*2100 mm Supporting pay-off frame size 1400*800*1300mm |

| weight | About 550KG±15KG. The supporting pay-off frame weighs about 150KG. |

| 3. Equipment configuration | |

| Motor | Mitsubishi/Huichuan |

| Pneumatic Components | 16 sets of SMC, air source treatment, flow control, actuator, control valve body are all made of SMC |

| visual system | Germany Basler CCD |

| module | 2 sets of THK/Shangyin linear modules |

| Lead screw | TBI |

| guide | Silver |

| sensor | Keyence/(Panasonic) fiber optics |

| belt | American Gates brand |

| Bearing | Japanese NSK brand |

| blade | It is made of imported alloy steel, processed by slow wire cutting, precision ground, and durable. |

Standard