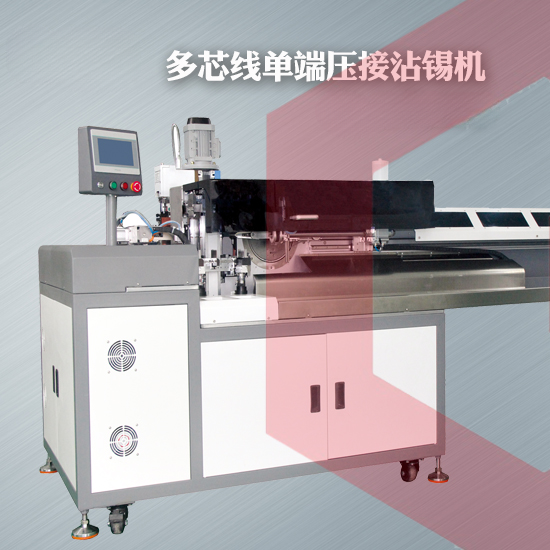

A Tin Dipping Machine is used in the manufacturing process to coat components with a thin layer of tin. This ensures improved conductivity, corrosion resistance, and solderability of electrical parts, wires, and connectors, making it essential for producing high-quality, durable electronic components.

A Tin Dipping Machine is an essential tool for any manufacturing process that requires high-quality tin coating for electronic components. By improving conductivity, corrosion resistance, and overall component durability, it addresses key user concerns and supports efficient, high-quality production. Its precision, versatility, and cost-effectiveness make it a valuable asset in achieving optimal performance and reliability in electronic and industrial applications.

Enhanced Conductivity and Solderability

Tin Dipping Machines apply a thin, uniform layer of tin to electrical components, significantly improving their conductivity and solderability. This is essential for ensuring reliable electrical connections and efficient performance in electronic devices. A consistent tin coating ensures that components can be easily soldered, reducing the risk of weak or unreliable joints.

Corrosion Resistance

The tin coating provided by these machines offers excellent resistance to corrosion and oxidation. This protective layer helps extend the lifespan of components by shielding them from environmental factors such as moisture, humidity, and chemicals, thereby reducing maintenance and replacement costs.

Precision and Uniformity

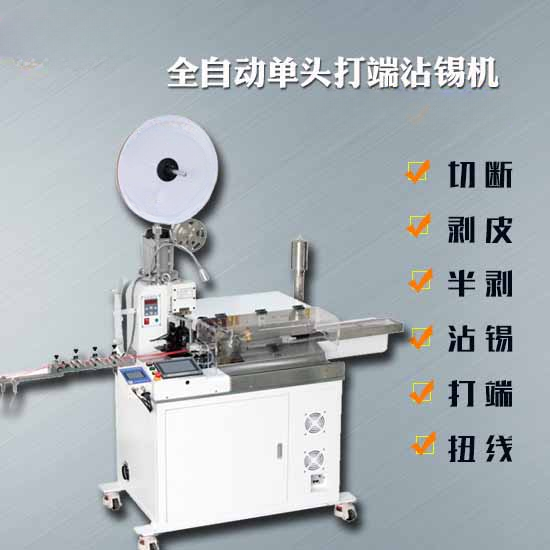

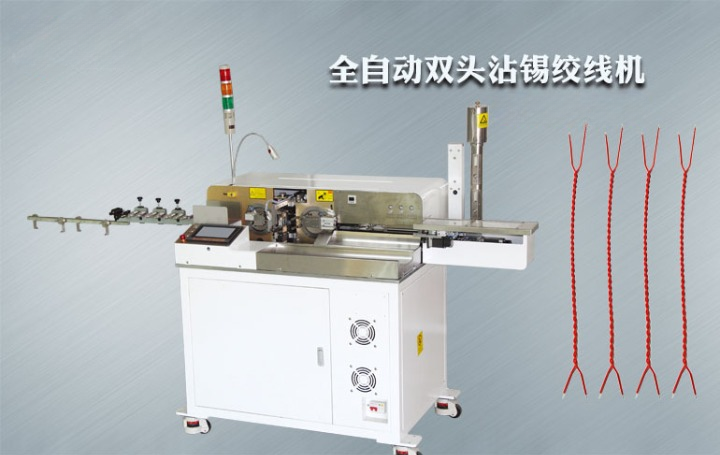

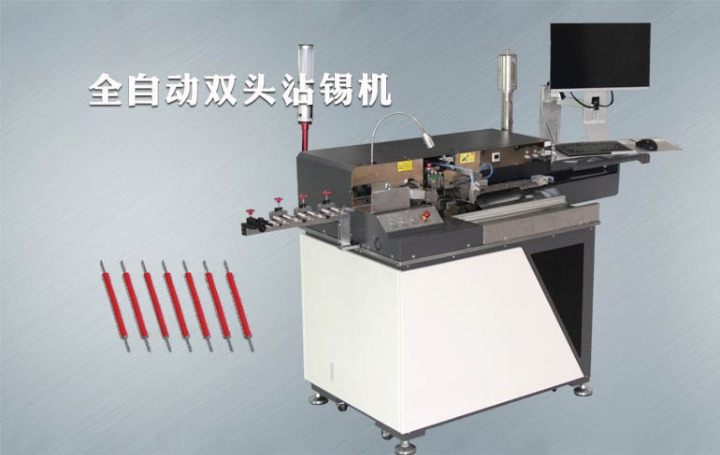

Modern Tin Dipping Machines are designed to ensure precise and even coating on various components. Advanced technology and control systems maintain consistent coating thickness and quality, which is critical for high-volume production and meeting stringent industry standards.

Versatility in Application

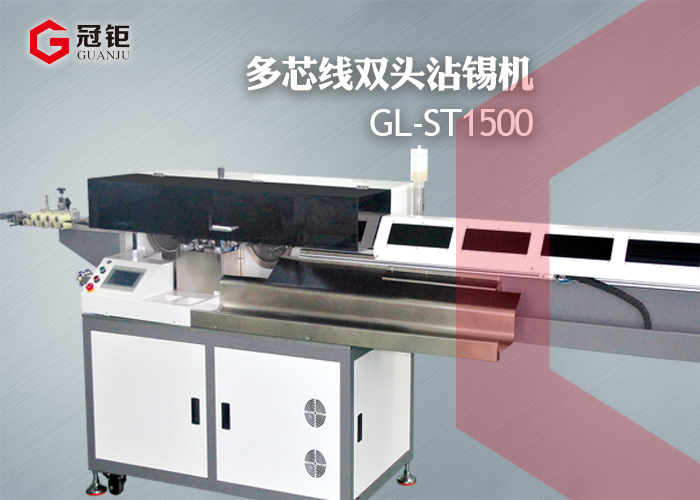

These machines can handle a wide range of components, including wires, connectors, circuit boards, and other electronic parts. This versatility makes them suitable for diverse applications across different industries, including automotive, telecommunications, and consumer electronics.

Hong Kong Suntex Electronics is a comprehensive manufacturer in the wire harness industry, providing you with a one-stop solution to your wire harness manufacturing needs. From connectors to wire harness processing equipment, from household appliances to aerospace; we are committed to providing customers with various solutions and constantly pursuing innovation and high quality.

|

|

|

|

|

|

|