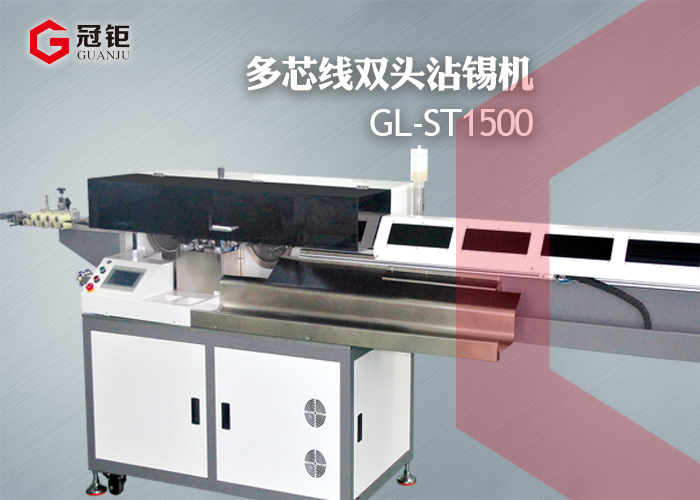

·Product parameters

Power supply: AC 220V/50Hz

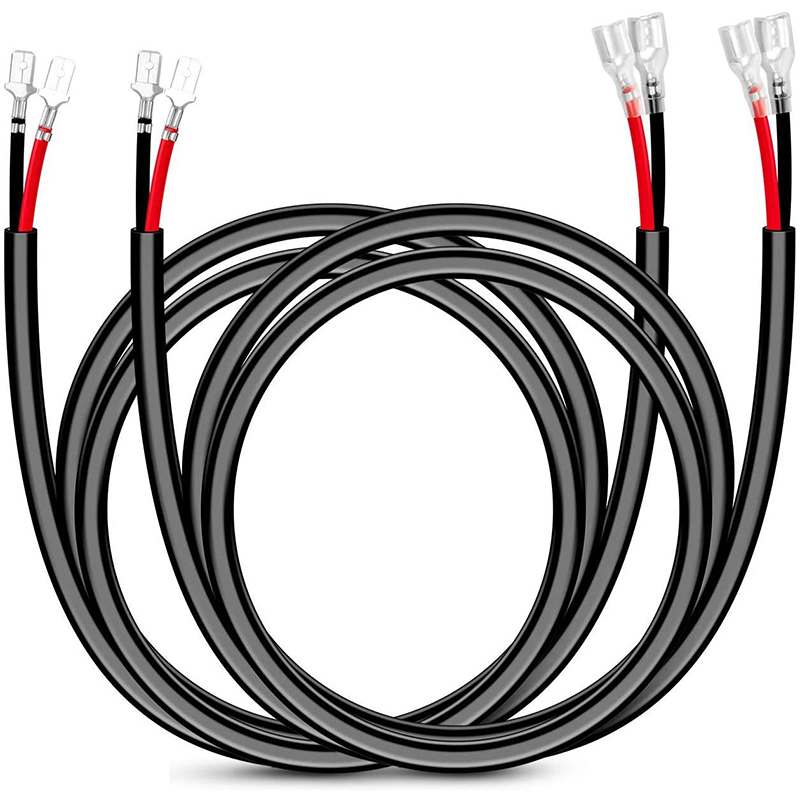

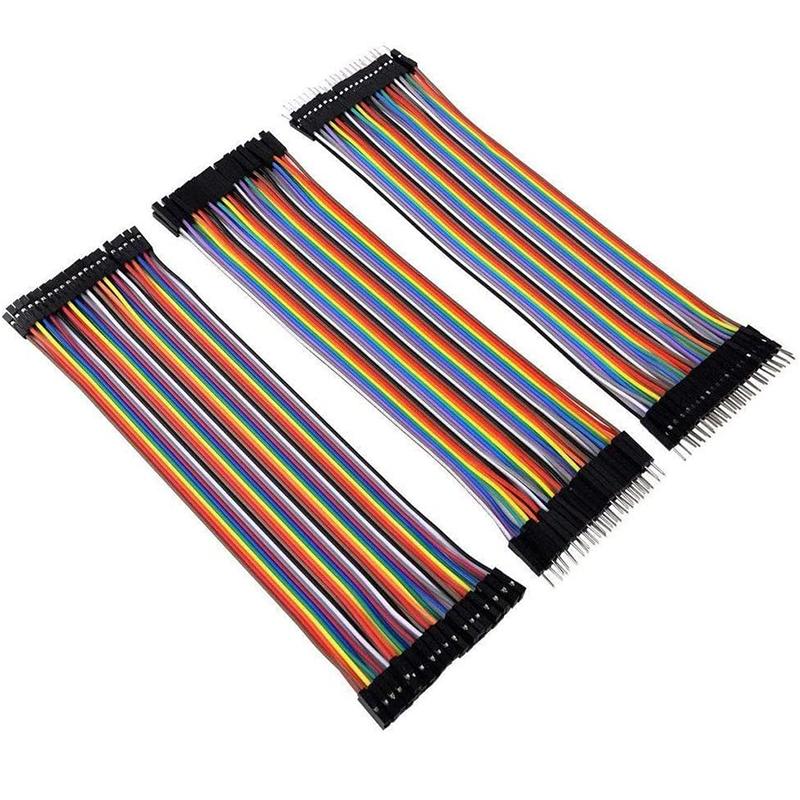

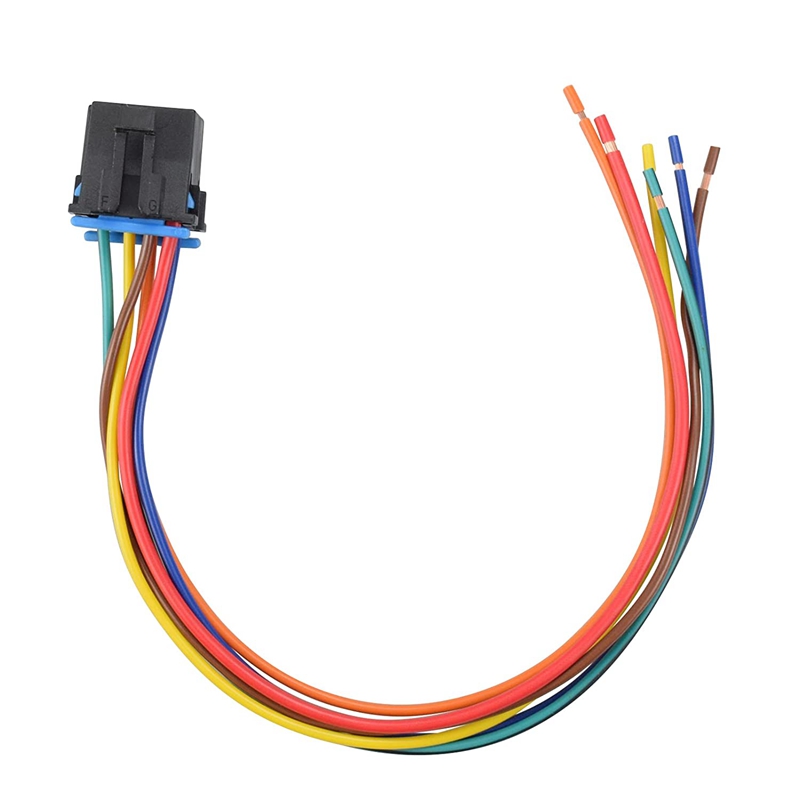

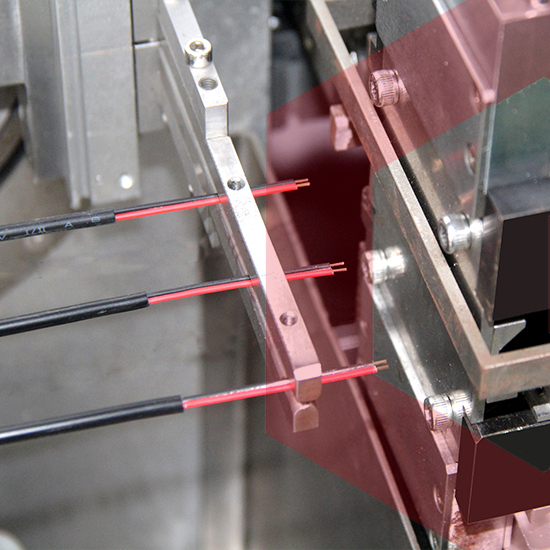

Main functions: cutting wire, double-head stripping, double-head twisting, double-head tin dipping

Front peeling length: 0-65mm

Front stripping core wire length: 0-15mm, tin dipping length 0-15mm

Length after peeling: 0-130mm

After stripping core wire length: 0-15mm, tin dipped length 0-15mm

Cutting line length: 80-1000mm (extended version can be customized)

Processable wire range: Φ3-Φ7. 8mm

Production capacity: 1500pcs/hour (length 300mm)

Air pressure: 0.5- 0.7Mpa

Air pressure monitoring: pressure alarm

Motor: Mitsubishi servo motor/domestic servo motor

Pneumatic components: domestic pneumatic components

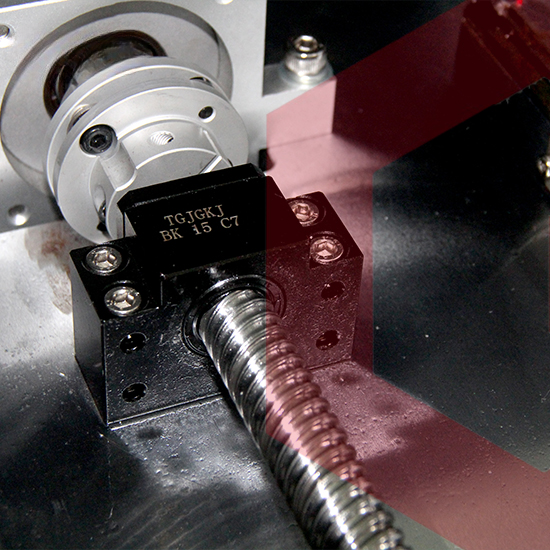

Screw: domestic screw

Guide rail: domestic guide rail

Belt: American Gates

Bearing: Japan NSK

Blade: imported alloy steel, slow wire processing, precision grinding

Body size: length 3810x width 850x height 1300 (mm)

Standard.