Automatic single-end tin-dipping machine, also known as automatic end tin-dipping machine, single-end tin-dipping machine, etc., can achieve wire cutting, single-end tin-dipping, double-end peeling, single-end half-peeling, single-end twisted wire, single-end tin-dipping and other functions.

The production wire range of the automatic end tin-dipping machine can be from AWG18 --AWG32, which can process 5 lines at the same time (also referred to as the 5-line machine), which greatly improves the production efficiency, and the automatic end tin-dipping machine has a wide range of practicability. An Automatic Tin Dipping Machine is a specialized piece of equipment designed to automate the process of tinning, which involves coating metal components, such as wires or terminals, with a thin layer of tin. This process is commonly used in electronics manufacturing to improve solderability, prevent oxidation, and enhance the conductivity and longevity of metal parts.

Automation and Efficiency: The machine automates the tin dipping process, reducing manual labor and increasing production speed. This ensures consistent and precise tinning across all components, leading to higher productivity and lower operational costs.

Temperature Control: Advanced tin dipping machines come with precise temperature control systems, ensuring that the tin remains at an optimal temperature for coating. This prevents overheating or underheating, which could affect the quality of the tin coating.

Adjustable Dipping Speed and Depth: The machine allows for adjustable dipping speed and depth to cater to different types of components and tinning requirements. This flexibility is essential for manufacturers who deal with a variety of products.

Maintenance and Durability: These machines are built with durable materials and are designed for easy maintenance, ensuring long-term reliable operation. Regular maintenance is simplified with accessible components and clear instructions.

An Automatic Tin Dipping Machine is an essential tool for industries that require precise and efficient tinning of metal components, helping to ensure product quality and operational efficiency. Welcome your consultation!

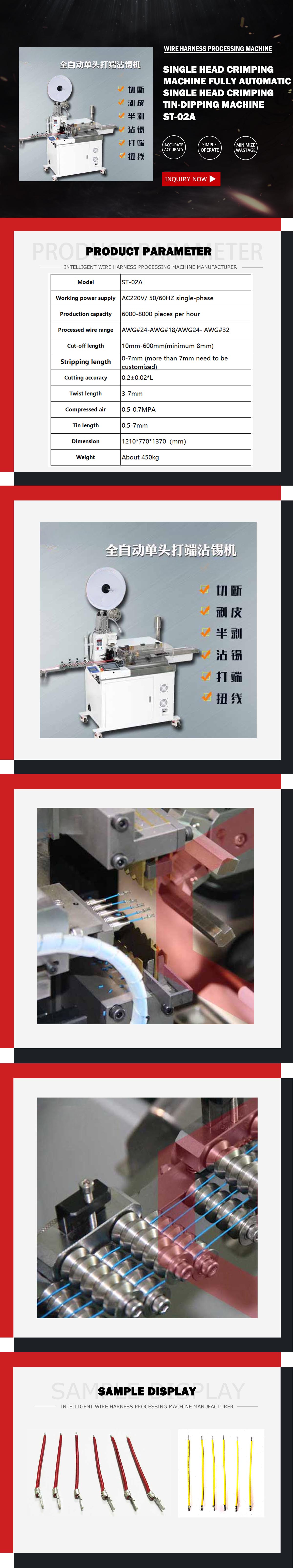

·Product parameters

model | ST-02A |

Working power supply | AC220V/50/60HZ single phase |

Capacity | 6000-8000 items/hour |

Applicable wire | AWG#24-AWG#18/AWG24-AWG#32 |

Cut off length | 10mm-600mm (the shortest length can be 8mm) |

Peeling length | 0-7 mm (above 7mm needs to be customized) |

Cutting accuracy | 0.2±0.02*L |

Twist length | 3-7mm |

compressed air | 0.5-0.7MPA |

Dip tin length | 0.5-7mm |

Dimensions | 1210*770*1370 (mm) |

weight | About 450kg |

Standard.